Both paperboard and plastic remain as widely popular packaging materials. Yet, negative perceptions of plastic persist due to the commonly misplaced notion that paper is “natural” whereas plastic is not. This perception has pushed retailers and brands to make the switch away from plastic to paperboard but not without consequential environmental impacts.

The increase in demand for paperboard packaging has surfaced serious environmental concerns, often unspoken such as deforestation, water pollution and increased greenhouse gas emissions, sparking a larger conversation on which material is more sustainable – paperboard or plastic? Here, PakTech unpacks this ongoing debate comparing the two materials from a holistic point of view.

A Full Life Cycle Perspective

A strong presumption exists among consumers that paperboard is somehow “natural.” But upon reflection, neither paperboard nor plastic really exist “in nature”: both are human made through large-scale processes that have environmental costs but provide significant benefits in return – from protecting our food to ensuring hygiene - that necessitate their use in today’s society.

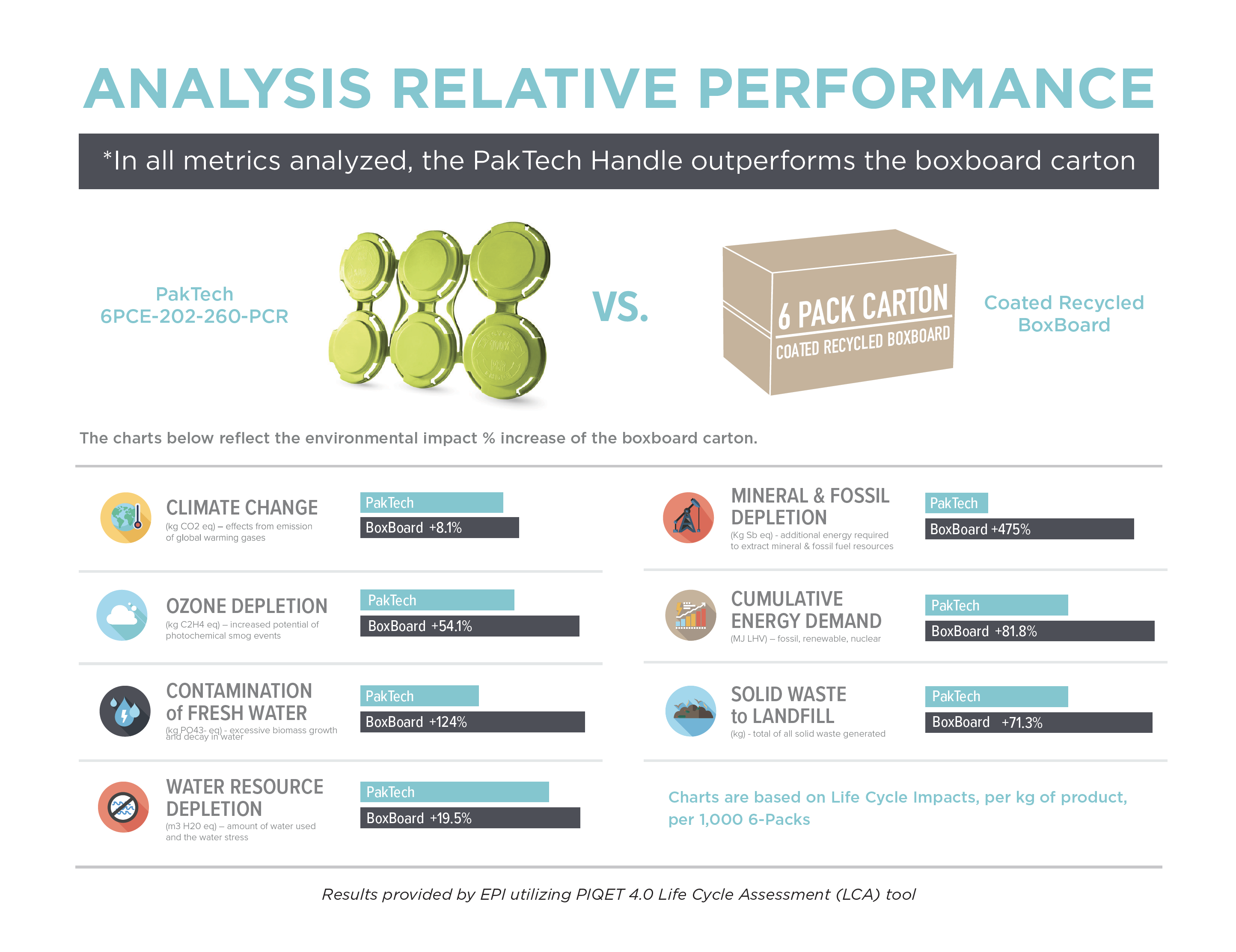

With this in mind, how can consumers make more responsible choices? They can do this by weighing the relative costs and benefits of each material from a life cycle perspective, taking into consideration the production, use and waste stages. When evaluated from this perspective, it becomes clear that plastic, particularly recycled plastic, performs better than paperboard.

Take resource intensiveness for instance, the pulp and paper industry is one of world’s heaviest user of fresh water, requiring billions of tonnes per year while also being heavily energy-intensive to power pulp mills. The increase in demand for paper is putting pressure on supply chains (two billion trees are cut down each year for packaging alone), threatening biodiversity while deforestation reduces nature’s carbon storage capacity during a time when its role is critical to tackle climate change. In addition, while paperboard is perceived as more “natural,” the processing stage relies on chemicals to pulp woodchips – a significant source of water pollution.

PakTech handles are manufactured more efficiently in comparison. While conventional plastic already embodies a smaller carbon footprint compared to paperboard due to less energy required for its production and transportation, PakTech handles perform even better by requiring 90% less energy than virgin plastic. Created from recycled feedstock, they do not deplete natural resources, reduce fossil fuels and avert plastic waste from our environment.

It also shows superior qualities during the use and resuse stage. Thanks to attributes such as amenability for strong and flexible parts, water-resistance, durability, and structural soundness, plastic is the ideal reusable material, a packaging format which shows better environmental performance than their single-use counterparts. A 2020 paper from Reloop showed that reusable HDPE bottles produce 65% less carbon emissions that single-use HDPE bottles. Meanwhile, the weak structural integrity of paperboard makes it unsuitable for reusable packaging and means it becomes easily damaged, creating unnecessary waste.

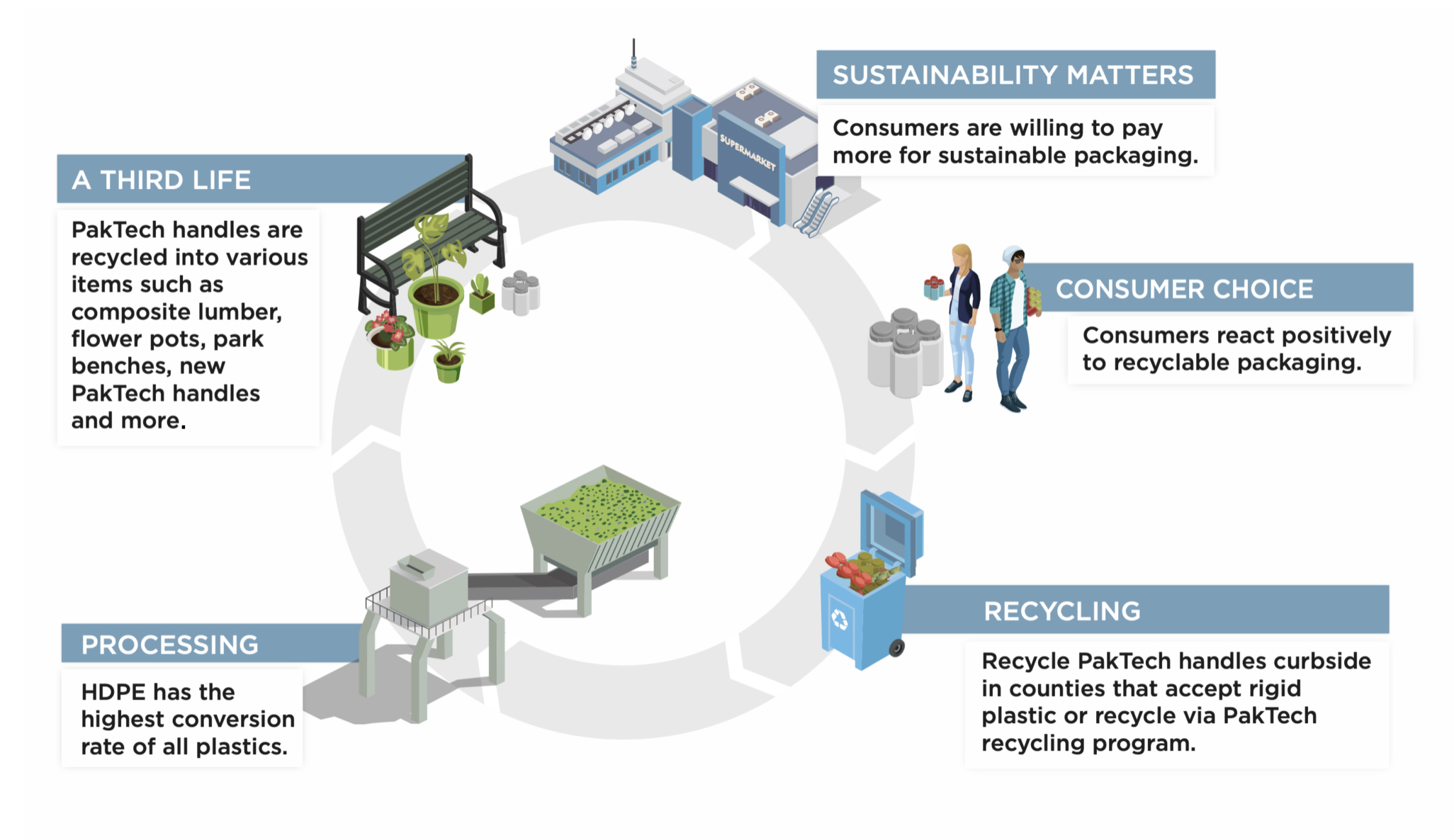

And when it comes to recyclability? Paperboard is often chosen over plastic as consumers immediately recognise it as recyclable. In reality, recycling paperboard is more tricky than assumed as its recyclability is compromised when contaminated (think greasy pizza box) or coated with resin to create moisture resistance properties.

Further, when paperboard is reprocessed into new products, the quality of the fibres diminishes with each treatment, resulting in only a 17% yield rate for recycled material. When it comes to HDPE, PakTech’s material of choice, the material retains 100% of its full reuse properties when recycled into new products almost indefinitely. Further, plastic recycling uses 65% to 88% less energy than producing virgin plastic, as opposed to 25% less energy for recycled paperboard than from new materials.

Importance of Choosing Circular Material

While the plastic versus paperboard debate rages on, the demand for circular plastic is increasing. Businesses are making strides in both the uptake of mono-material plastic packaging to enhance recyclability and packaging with increased recycled content while regulators across the UK and Europe are setting legislation to incentivise producers and importers to use more recycled plastic content.

At PakTech, our material of choice is 100% recycled HDPE for its circular attributes that reduce unnecessary waste such as water-resistance and durability that further reduce our reliance on finite resources. PakTech handles are always second life products, even third when it comes to our Pak to Pak can carriers that are made out of recycled PakTech handles.

PakTech has been using 100% recycled plastic to produce our handles since 2012, making us a pioneering solutions-provider in sustainable and circular packaging. With our 100% recycled, reusable and recyclable handles, consumers and businesses will be reassured that they’re making a smart and sustainable choice when it comes to packaging.